3D printing: beacon of a new scientific revolution?

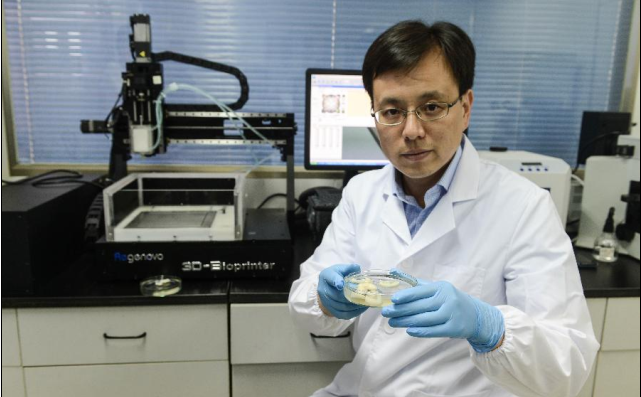

Recently, a biomaterial 3D printer was developed by Prof. Xu Ming’en and his team from the Institute of Biomedical Engineering and Instrument Science at Hangzhou Dianzi University. The printer can print cartilage tissues and renal cells, although it is not yet capable of printing living organs.

3D printing technology works via a sequential layering process, which originally earned it the name “additive manufacturing”. It was not until 1996 that the current name was coined, but a catchier and simpler title helped the technology become widely known. As it can integrate design and manufacturing processes, shorten the period of research and development for new products and reduce wear and tear, 3D printing has been one of the most anticipated and watched technological developments during the past three decades. Researchers have also made unremitting efforts to improve its equipment and materials.

The world’s first 3D printer was created in 1984 in the U.S. Two years later, the world’s first 3D printing equipment manufacturer also opened in the U.S.

Significant strides have especially been made in 3D printing technology since the new millennium. In 2005, the world’s first high-precision 3D color printer made its debut. That same year, the University of Bath initiated a project to produce a “self-replicating machine”, a 3D printer that could manufacture a copy of itself.

In China, some universities and research institutes have also been engaged in research and development of 3D printing technology. Along with Hangzhou Dianzi University, Tsinghua University is leading the way among a handful of Chinese universities that are committed to this research field, said Xu Ming’en.

Xu indicated that his team’s biomaterial 3D printer will produce materials and tools in biomedical scientists’ and doctors’ labs; it will be put on the market this year. “Although this equipment cannot print living organs, its ability to print living cells is among the most advanced technology in the world,” said Xu.

As early as ten years ago, Sichuan University’s School of Manufacturing Science and Engineering began offering a course on “3D printing technology—prototyping”. Mei Xiaoqin, an associate professor who participated in the introduction of the course said that students are taught the principles of 3D equipment construction and composition, the social application of 3D printing, and future development and bottlenecks of 3D printing technology. Students are also trained in practical use of 3D printers.

“Now this course has been offered in seven to eight higher education institutions in China, and our school has sent students to learn 3D organ printing technology in the U.S.,” said Mei.

One of the biggest developments in 3D printing has been the increase of printing materials. Now approximately 107 kinds of material, varying in flexibility and transparency, are available. “Both its equipment and materials are developing rapidly. Although it is still in a somewhat unrefined state, this technology has already demonstrated its beauty,” affirmed Mei.

Countries with 3D printers include the U.S., Japan, the U.K., Germany and China. 3D printing technology is particularly sought after in industry and manufacturing. In the medical industry, some simple tissues can be printed, such as bone tissue, veins and bile ducts, which can be implanted in patients to assist regeneration of damaged areas. In aerospace, 3D printing has been widely used in the design and manufacturing of new airplanes.

Perceiving its potential in industry and manufacturing, some countries have given 3D printing strategic importance. In 2012 for instance, the U.S. listed 3D printing technology as one of the most important manufacturing technologies and elevated it to the level of national strategy. Scholars have pointed out that U.S. is eager to find a new point for technological growth to revitalize its manufacturing sector and 3D printing may provide such an opportunity. In Europe, some universities, enterprises and governments have established a technological alliance to further develop 3D printing capabilities.

People are anticipating a promising future of 3D printing technology, and some even believe it can usher in the third Industrial Revolution. Academia, however, has kept a reserved attitude.

Jiang Xiaoyuan, director of the School of History and Culture of Science at Shanghai Jiao Tong University, noted that two kinds of people tend to describe the 3D printing technology as world-changing: those seeking to profit from it and blind believers of science who are always prone to interpret the next scientific discovery as a miracle. Jiang warned that when evaluating the influence of certain technologies on future society, we need to be weary of and alert to their possible negative effects.

Mei Xiaoqin believes that even as it becomes more advanced, 3D printing technology will never completely replace the conventional machinery-based manufacturing industry simply because it will never achieve the same scale. “3D printing is characterized by personal customization. Like apparel, most products are mass-produced for a wholesale market; only a small portion of high-end products are customized.”

“People may have blind enthusiasm for 3D printing technology, but the high profile it has received is, if anything, indicative of just how strong the demand for it is,” asserted Xu Ming’en. While currently it still faces technological difficulties, 3D printing will undoubtedly change people’s modes of production and way of life in various aspects, he added.

Prof. Ma Laiping from Shandong University has long been committed to the history of science in modern and contemporary China. He believes that it is too early to say that 3D printing will bring about enormous changes to societal patterns of production and consumption considering its many current limitations. Ma’s caution stems in part from the high cost of individual machines and the limited materials that can be used for printing. Additionally, he pointed out that the 3D printing’s accuracy still has significant room for improvement and the scope of application needs to be expanded. On the whole, he suggests that 3D printing technology is merely a supplement to conventional manufacturing, or a vibrant force that may stimulate changes to conventional manufacturing.

However, Ma still advised that we need to be fully aware of 3D printing’s potential to spur shifts in production and consumption. In recent years, 3D printing technology has seen rapid development and an expanded scope of application. Developed countries like the U.S. are investing considerable resources in further developing and refining 3D printing.

Ma did not dismiss the possibility that 3D printing technology may lead to another new scientific revolution. He said that any new technology that does so would have to have a ripple effect on other areas of science, and reach a state of maturity such that it has spread to various sectors and caused changes to patterns of production, in turn causing changes to productive relations. “Only if it satisfies these requirements can 3D printing technology lead to tremendous changes to societal patterns, thus having historic value on par with the discoveries and technologies of the previous three scientific revolutions,” he concluded.

Tang Hongli is from Chinese Social Sciences Today.

The Chinese version appeared in Chinese Social Sciences Today, No.487, Aug 12, 2013.

Translated by Jiang Hong

Revised by Charles Horne

Chinese link:

http://www.csstoday.net/xueshuzixun/guoneixinwen/83651.html